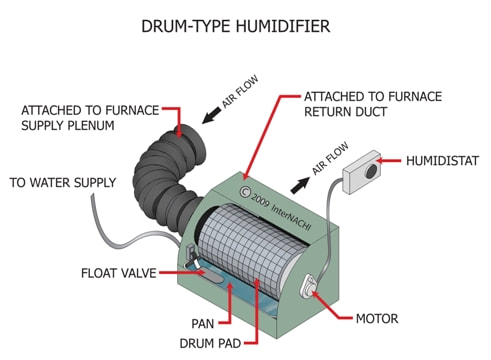

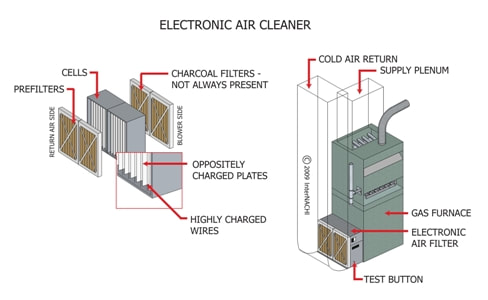

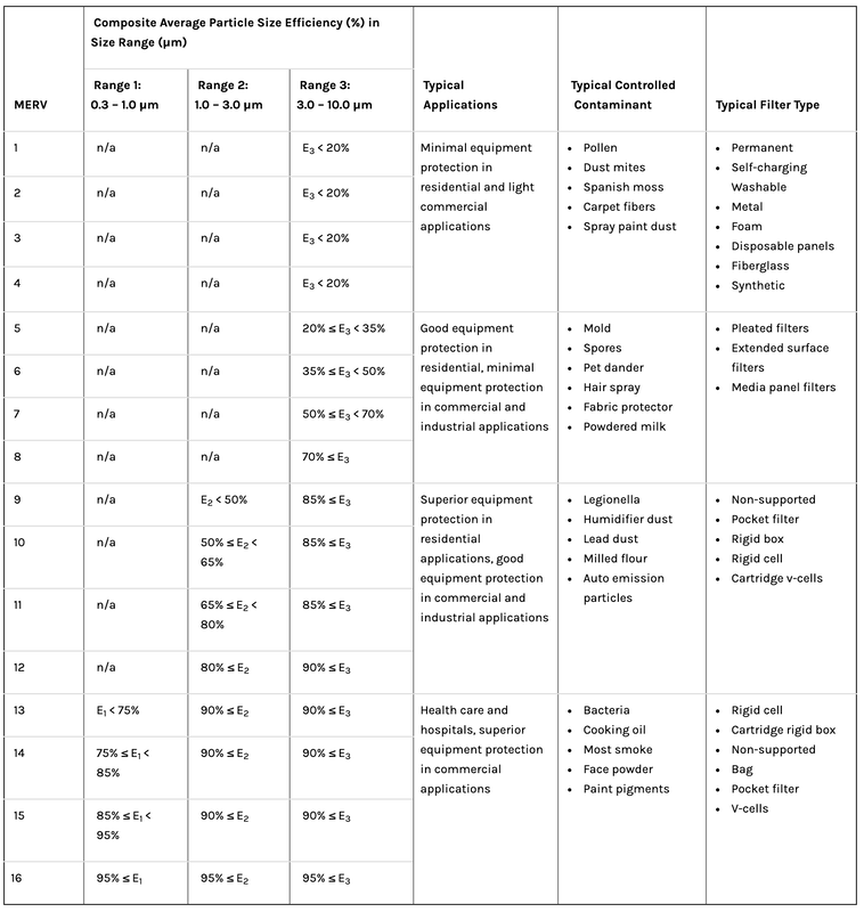

A wood-decay or xylophagous fungus is any species of fungus that digests moist wood, causing it to rot. Some species of wood-decay fungi attack dead wood, such as brown rot, and some, such as Armillaria (honey fungus), are parasitic and colonize living trees. Excessive moisture above the fibre saturation point in wood is required for fungal colonization and proliferation. In nature, this process causes the breakdown of complex molecules and leads to the return of nutrients to the soil. Wood-decay fungi consume wood in various ways; for example, some attack the carbohydrates in wood, and some others decay lignin. The rate of decay of wooden materials in various climates can be estimated by empirical models. Wood-decay fungi can be classified according to the type of decay that they cause. The best-known types are brown rot, soft rot, and white rot. Each produce different enzymes, can degrade different plant materials, and can colonize different environmental niches. Brown rot and soft rot both digest a tree's cellulose and hemicellulose but not its lignin; white rot digests lignin as well. The residual products of decomposition from fungal action have variable pH, solubility and redox potentials. Over time this residue becomes incorporated in the soil and sediment so can have a noticeable effect on the environment of that area.  Invermere home inspection services Invermere home inspection services Building codes vary from region to region (with amendments) and not all the jurisdictions follow the ICC or adopt ICC codes at the same time. In most cases they all basically include the same restrictions. Some codes have been found to be less restrictive. Many of them concur that the exception to the 35-foot minimum run length is when the appliance manufacturer's installation instructions specify maximum lengths with particular models. In this case, the make, model and installation instructions need to be provided to the building inspector and sometimes a permanently mounted sign or placard is placed behind the dryer identifying the overall length of the exhaust duct and the respective model that the house was approved with. A summary of the typical codes relating the dryer venting is as follows: Dryer vent systems shall be independent of all other systems and shall convey the moisture to the outdoors. Terminations shall be a minimum of three feet from property line and 12" above the ground and not exhibit any type of screen. Vents and duct connections shall be connected mechanically (with sheet-metal screws or rivets) and shall not protrude more than 1/8" into vent. Exhaust vents shall be equipped with a back-draft damper and no screen. Vents shall be constructed of minimum 0.016-inch-thick (0.406 mm) rigid metal ducts, having smooth interior surfaces with joints running in the direction of air flow and having a minimum interior diameter of 4". Flexible duct shall not be concealed within the construction. The maximum length of a 4-inch (102 mm) diameter exhaust vent shall not exceed 35 feet (7620 mm) from the dryer location to wall or roof termination and shall terminate with a full opening exhaust hood. A reduction in maximum length of 2.5 feet for each 45-degree bend and 5 feet for each 90-degree bend shall apply. Installations where this length is exceeded shall be installed in accordance with the manufacturer's installation instructions.  Invermere home inspection services Invermere home inspection services Maintenance Moisture from humidifiers may support microbial growth on wet surfaces where it can condense during cold weather. Humidifiers that discharge small droplets of water from a reservoir are prone to support mold growth. Moisture accumulation inside dirty ductwork creates a suitable environment for mold growth. The reservoir of the humidifier becomes contaminated, to some degree. Humidifiers should be considered potential sources of mold growth. All humidifiers use water, so delayed maintenance at a humidifier may cause indoor air-quality issues for sensitive people. If there is a reservoir of water in the humidifier, then it needs to be drained and cleaned regularly. Humidifiers need regular maintenance, including cleaning, and the removal of lime and other residue. Any moisture pads or media need to be replaced regularly, usually every month while the humidifier is in regular operation.  Invermere home inspection services Invermere home inspection services Home heating, ventilation, and air-conditioning (HVAC) systems that have a central air handler and ducting should be equipped with air filters. The purpose of air filters is to remove particulates (such as dust) from the air stream to protect the system from degradation by keeping internal components clean of particulate build-up that could cause lower equipment efficiency, reduced reliability, and diminished heat transfer.  HVAC filters are typically located in the return duct line adjacent to the air handler or on the back of the return register grille(s), where they trap particulates in the air pulled into the return ducts by the air handler. Filters are available in a range of styles, materials, and sizes. They’re generally 1 to 4 inches thick, made of polyester and/or fiberglass, and styled in a flat or pleated pattern. Filters use either mechanical filtration or electrostatic filtration to remove particulates from the air. Mechanical (i.e., surface media) filtration is the capturing of particulates through a dense fiber medium. The filter media are typically pleated, which allows more surface area to capture debris. Electrostatic filtration uses electrostatic precipitation to remove particulates. Some filter models on the market combine mechanical and electrostatic filtration. Filters can be replaceable, or washable and reusable. Replacement filters are typically made of synthetic media or fiberglass. They should be replaced every three months or sooner, if needed, especially if the HVAC equipment is used continuously. Filters loaded with particulates should be discarded. Washable filters typically use electrostatic filtration and are made of aluminum mesh or foam rubber. They should be removed for cleaning once every one to three months, rinsed with water or cleaning solution, air dried, and then re-installed. If washable air filters are not dried properly, they have the potential to attract mold. Whole-house air filters come in four main types: flat filters, electronic filters, ultraviolet filters, and extended media filters.  Flat Filters If there is a forced-air furnace installed in the house, the HVAC system likely has a rudimentary air-filtration system, which is a thin plastic filter provided by the unit's manufacturer to capture very large particles. There are also matted-fiberglass filters that homeowners install. They should be changed once a month. When they clog, they stop working. And a clogged filter can damage the system over time because of the air restriction. The image above is of a few rudimentary flat 1-inch air filters.  The image above is of a manufacturer's filter made of plastic.  Electronic Filters Electronic air filters remove airborne particles from the air electronically. High-efficiency filters can remove about 80% to 90% of all particles. Some electronic filters have a charged media pad or mat that is made of fiberglass, cellulose, or some similar material. When these pads get clogged or dirty, they usually cannot be washed and require replacement. Some electronic air filters are two-stage filters. Air particles pass through not just one filtering device, but two electrically charged filters. There is typically a permanent screen or pre-filtering device. This first filter catches the larger particles before moving to the first electronic filter. In the first filter, the particles receive an intense positive charge. The positively charged particles are then attracted to the next filter that has collector plates. These plates are alternately charged with positive and negative voltages. The particles adhere to the negatively charged plates until the filter is removed and washed. Most devices have a built-in performance-indicator light that glows red when the unit is operating normally. Many electronic air filters have a pre-filter (or lint filter) and an after-filter. The after-filter is installed after the second set of charged collector plates. Electronic air filters need to be cleaned at least once every six months. Most electronic air filters can be washed in the dishwasher, but the manufacturer's recommendations should be followed. When the filters are put back into place, they must be re-inserted correctly so that the air flows in the proper direction. There are usually directional arrows marked on the filter components to guide their proper installation. Ultraviolet Filters People worried primarily about germs may consider an ultraviolet filter. The ultraviolet light zaps airborne bacteria and viruses into oblivion, which is why hospitals use UV air filters in tuberculosis wards. Extended Media Filters These filters are several inches thick and require a professional to install into the ductwork. HVAC Filter Performance and MERV There are two elements of HVAC filter performance:

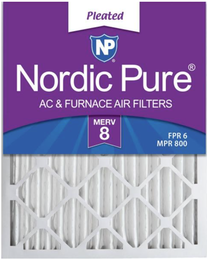

Another measure of a filter’s effectiveness at removing particles is particle size efficiency, which is the fraction (or percentage) of particles captured on a filter. Particle size efficiency is measured across three particle‐size bins: 0.3 to 1.0 μm; 1.0 to 3.0 μm; and 3.0 to 10.0 μm. The percentages correspond to MERV ratings as shown in the table below, which is based on the National Air Filtration Association’s Understanding MERV Guide, and the U.S. Environmental Protection Agency’s (EPA) Residential Air Cleaners (Second Edition). The image above is of a Honeywell 20x20x5 MERV 13 air filter. Pressure Drop or Airflow Resistance The second aspect of HVAC filter performance is pressure drop or resistance to airflow. As the air stream passes through the filter, it decreases its velocity due to the resistance of the filter. This resistance is measured in inches of water column (IWC, or in. w.c.) at either a specific face velocity or airflow rate. The resistance to airflow of a brand new filter is called the “initial pressure drop,” whereas the resistance when the filter is loaded with particulates is called the “final pressure drop.” The contribution of the filter to the total system pressure drop is typically 20% to 50%, depending on the system's configuration, filter efficiency, and loading condition. HVAC system engineers and designers are supposed to take the initial pressure drop of the filter into account when determining how to size HVAC equipment and related ductwork for residential and commercial buildings. Resistance Causes Energy Consumption The resistance to airflow in a high static pressure system causes the controls of brushless permanent magnet (BPM) blower motors to increase speed and power draw to maintain system airflow, resulting in an increase in energy consumption. Permanent split capacitor (PSC) blower motors do not have airflow controls like BPM blower motors and thus will not increase power and speed to maintain system airflow. Instead, since PSC blower motors cannot adjust speed or torque, they reduce power draw and airflow in response to increasing system pressures. This is known as “fall off,” when the motor will stop pushing even though the fan continues to turn. As a result, the run time necessary to cool or heat the ambient air to the thermostat’s set‐point temperature is extended, which can lead to an overall increase in energy use. In addition, excessive pressure drop can damage the furnace due to overheating, can freeze condensing coils in air conditioning units, and can burn out blower motors. It’s important for homeowners to purchase filters with a pressure drop performance that meets their HVAC system's specifications in order to run their equipment efficiently and prevent damage. The Air Conditioning Contractors of America (ACCA) Manual D Residential Duct Systems offers guidance for sizing residential ducting systems, including sizing HVAC filters for pressure drop in the system. High MERV Can Clog Faster The accumulation of dirt and particles can greatly increase pressure drop across a filter. Because high-MERV filters can trap more particles, they are likely to clog faster than low-MERV filters. Choosing filters with deeper pleats (e.g., 4-inch pleats) will increase the surface area of the filter and potentially reduce the pressure drop while increasing or maintaining a high MERV rating. For example, a filter that has 4-inch-high pleats has twice the surface area of a filter with 2-inch-high pleats. If a homeowner wants to use a very high MERV filter, it may require the alteration or replacement of ducting if the pressure drop of the filter is greater than the pressure drop allotted to the filter in the system design. Another option is to advise the homeowner to purchase separate air filtration equipment that can clean the indoor air without impacting the performance of the HVAC equipment. Filters should be selected as part of the overall duct design process, as described in the Air Conditioning Contractors of America (ACCA) Manual D Residential Duct Systems. Accessible for Homeowners Making filters accessible for easy replacement and providing controls that tell homeowners when replacement is due will help to eliminate problems, such as clogging and filter collapse, which are more likely to occur with higher MERV filters. If exceptionally high filtration is desired (above MERV 13), some sources suggest using separate air filtration equipment with a HEPA filter that can clean the air without impacting furnace performance, although their functionality is localized, as opposed to whole-house. How to Select a High MERV Filter The builder or HVAC contractor should design the HVAC duct system using ACCA Manual D to determine the maximum static pressure that the filter can have and select a MERV 6 or higher filter within that limit, and adjust the duct size, duct length, and/or filter surface area as necessary to ensure that the total pressure drop across the system does not exceed the blower fan motor’s limit, given the size of the unit. Recommend MERV 6 or Higher In homes with ducted HVAC equipment, the HVAC inspector should look for HVAC systems with filters that are rated MERV 6 or higher. The HVAC technician or builder should have ensured that the HVAC system can accommodate the pressure drop associated with higher MERV filters. When certifying ENERGY STAR-certified homes, the HERS rater inspects to make sure that MERV 6 or higher filters are installed. When assessing EPA Indoor airPLUS and DOE Zero Energy Ready certified homes, the rater verifies that MERV 8 or higher filters are installed.  The image above shows a 14x25x2-inch pleated MERV 8 air filter made by Nordic Pure®. Short Helpful Video from "This Old House" Enjoy this short helpful video about air filter types. Credits to: Internachi https://www.nachi.org/

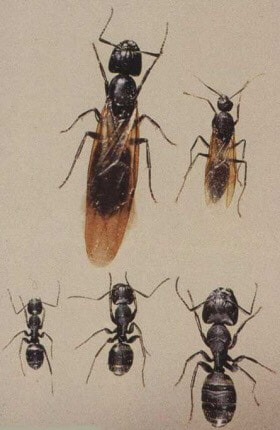

John Roberts Former Retired Electronics Specialist at British Telecommunications (BT) (1967–2000)Author No , for propane you are detecting flammable vapour. In a carbon monoxide detector you are detecting the absence of oxygen. The propane detector uses an infrared module thar sends 2 different wavelength of infrared to a photo detector. The wavelength are calibrated for propane, when the beams are altered by the propane it sounds an alarm. With carbon monoxide there is a coated silicon chip which when carbon monoxide is present rests with the coating altering its resistance and tripping the alarm. What are they?The red carpenter ant and the black carpenter ant are two of the most common types found in Canada. The red carpenter ant has a dark brownish-black body, with a reddish-brown upper body. The black carpenter ant is dark brownish-black all over. Carpenter ants are from 6 to 25 mm (.24 to 1 inch) long. A carpenter ant's body is divided into three segments, with a very slim waist separating the upper body and lower body. Their antennae are bent and in sections. Male and female adults have wings at mating time. Should I be concerned?Carpenter ants are well known for their ability to damage wooden structures. They are also a nuisance in homes as they search for food. Carpenter ants eat both plant and animal matter. Their natural food sources are insects, other small invertebrates, and sweet body fluids from aphids and other insects. Protein and sweet foods found in and around homes also provide food for foraging workers. Carpenter ants build nests by burrowing into wood. They dig tunnels (called galleries) much longer than those created by termites. The wood is not eaten, but thrown from the nest as sawdust-like shavings. How can I get rid of carpenter ants?Physical control

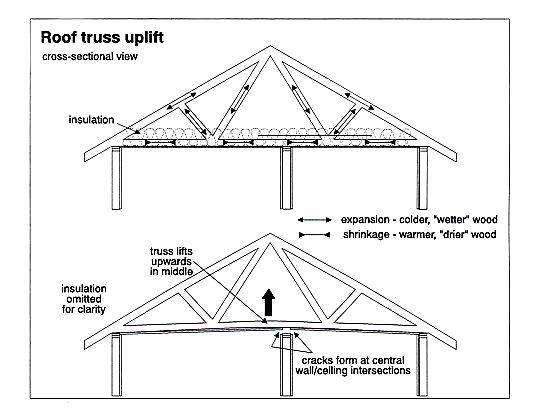

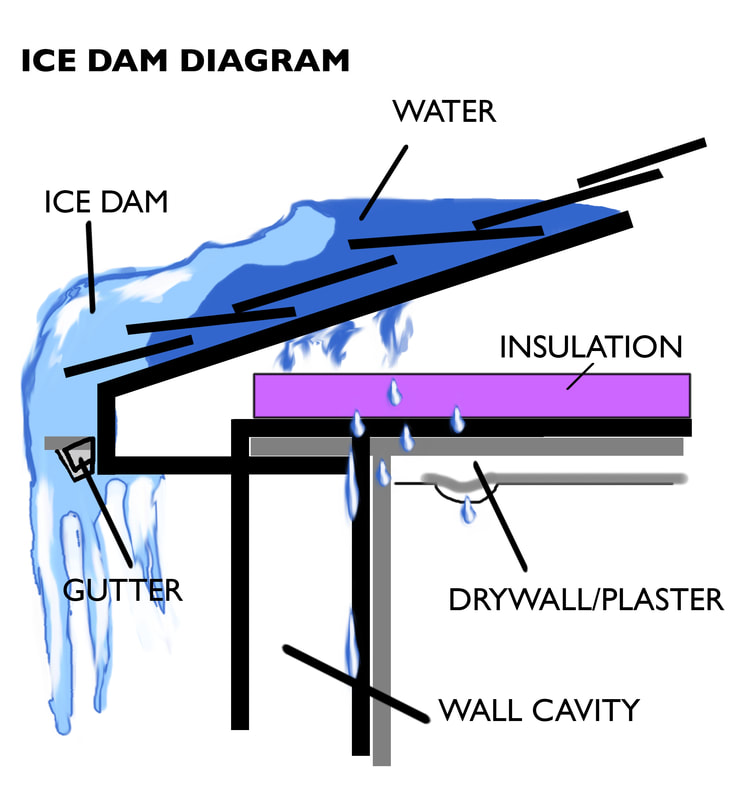

An ice dam is a ridge of ice that forms at the edge of a roof and prevents melting snow (water) from draining off the roof. The water that backs up behind the dam can leak into a home and cause damage to walls, ceilings, insulation, and other areas.

Canadian home inspection services. |

Archives

January 2024

Categories |

RSS Feed

RSS Feed